Design. Build. Deliver.

Discover the beauty of custom woodworking with over 46 years of experience and passion, creating unique furniture and cabinetry to fit your style and needs, using a range of finishes to suit your preference. Design, build, and delivery - turning your vision into reality.

About Brian Chitwood

I was 15 years old in 1977 when I took a woods class at my high school in Lincoln, Nebraska. Little did I know what that would lead to. I fell in love with woodworking and never lost that passion. I took all the woods classes I could and hung out in the woodshop during my free periods. I have been fortunate to work in some great cabinet shops and in a one-man shop as an apprentice that allowed me to learn from some great woodworkers. I never realized at the time that I was in “school”. Here I am, 46 years later and still love making and creating and designing. There is still something magical about seeing a tree cut on a saw mill and figuring out what to make with it. I’m amazed at the creativity of our Creator.

I spent many years in Central Iowa but the last 6 years we have called Ladysmith, Wisconsin home. My wife, Barb and I both love the north woods and especially enjoy the local rivers. We are blessed to fly fish these waters for bass, musky and trout.

Next Steps

If you are interested in having a piece of furniture made, the process might go something like this. A phone call is a great place to begin. During that call the conversation might include what type of piece you are looking for, style, type of wood preferred and what type of finish might best suit the application for the piece. Often times, a picture of a similar piece of furniture can be helpful in the process of designing exactly what you would want.

After the initial phone call, I can come up with a rough estimate of the cost. That sometimes determines if another step is needed. Once a design is agreed upon, it is helpful to have 50% of the cost up front to confirm you order. A lead time will also be discussed at this time.

After that, the build process begins. Pictures can be sent to show progress or one is welcome to stop by the shop and check things out for yourself. The final step would be delivery or pick up of your one of a kind piece.

Galleries

Canoe Build

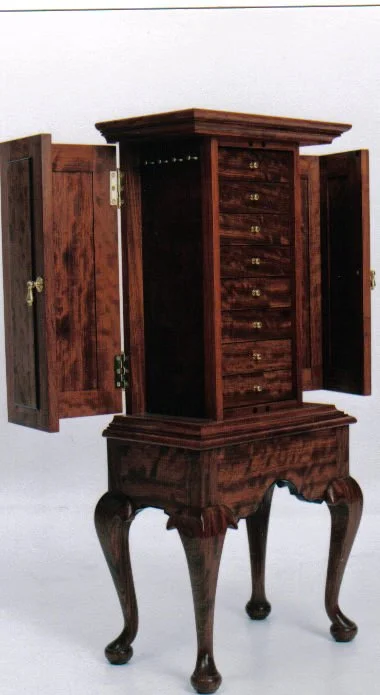

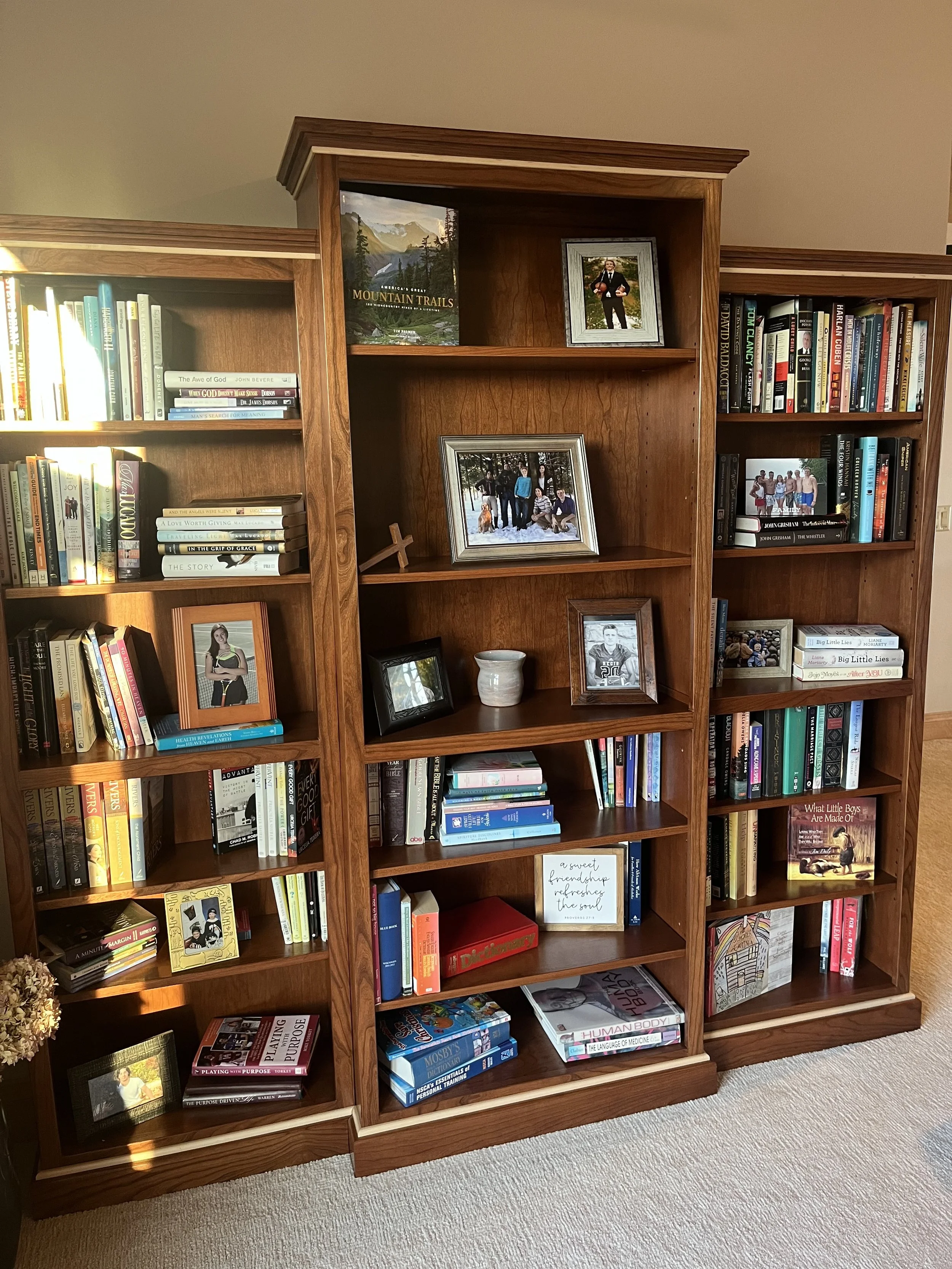

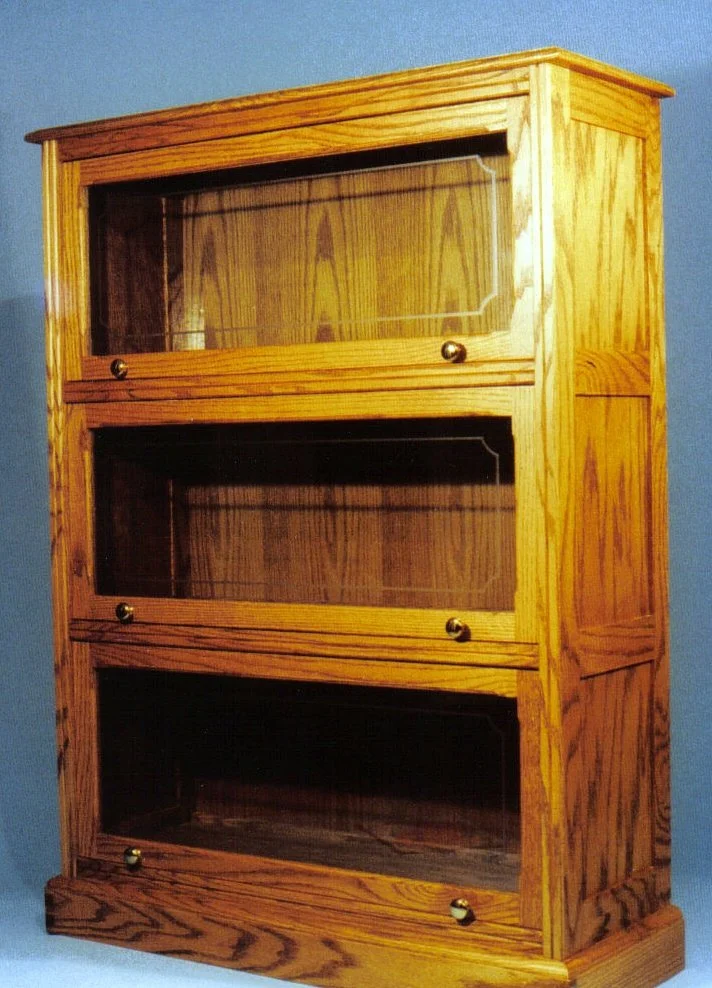

Custom Furniture

Misc. Projects

Articles

Here are a couple of articles from the past that featured a couple of pieces I made. One is an original design (Home Furniture) and the other (Woodwork Magazine) was highboy inspired by a period piece I had seen in a book of furniture by Carlyle Lynch.

Home Furniture - Read Article

Woodwork Magazine - Read Article

FAQ

What type of finish do you use?

The finish of a piece is the last step in making a great piece of furniture. I often get asked what type of finish I use and the answer is that I use a variety of finishes. Much of the choice of finish depends on what the piece of furniture or cabinet is used for. Much depends on the preference of the person that will be using and enjoying the piece. There are “film” finishes that offer much protection but are difficult to repair. These finishes often sit on top of the wood itself. There are “oil” finishes that offer less in protection but are nice to the feel and don’t have that “plastic” look to them. These finishes penetrate the wood and are easier to repair. I actually prefer them for many applications. There are water-based finishes that often look great on lighter woods if one doesn’t like the amber look of oil and polyurethane.

How long does it take to get something made?

That will vary on a lot of things. Factors that determine how long it takes to have a piece include the complexity of the piece, the availability of the lumber, as well as the number of projects I have currently underway. I will be completely honest with an estimate of when you could expect your project to be completed.

Can I stop by and take a look during the building process?

Of course! If you live close enough, I would welcome that.

Where do you get your wood?

From a variety of sources. I have salvaged several trees and had them sliced into lumber and then air dried them. I have purchased from Amish saw mills, wholesale lumber companies and even on rare occasion, from some box stores.

How does pricing work?

This varies on so many things. Things that influence the price of a piece include the different type of woods and materials that are involved. The complexity of a project, the hardware or other specific, the amount of labor involved all influence the final cost. If you have a specific budget in mind, I will do my best to work with you.

Contact

I’d love to design, build, and deliver for you! Reach out to learn more.